Superabsorbent polymers (SAPs) such as Polymer Innovations Watersave product are unsuitable for dam sealing due to their to provide a durable, reliable seal, their potential incompatibility with dam materials, and their challenges in achieving uniform coverage over large and irregular dam surfaces.

When it comes to the essential task of dam sealing, ensuring the structural integrity and water-tightness of these vital infrastructure components is of paramount importance. Various methods and materials have been employed to achieve this, but one that has piqued interest in recent years is superabsorbent polymers (SAPs). In this blog post, we’ll delve into what superabsorbent polymers are, how they work, and why they often prove inadequate for dam sealing projects.

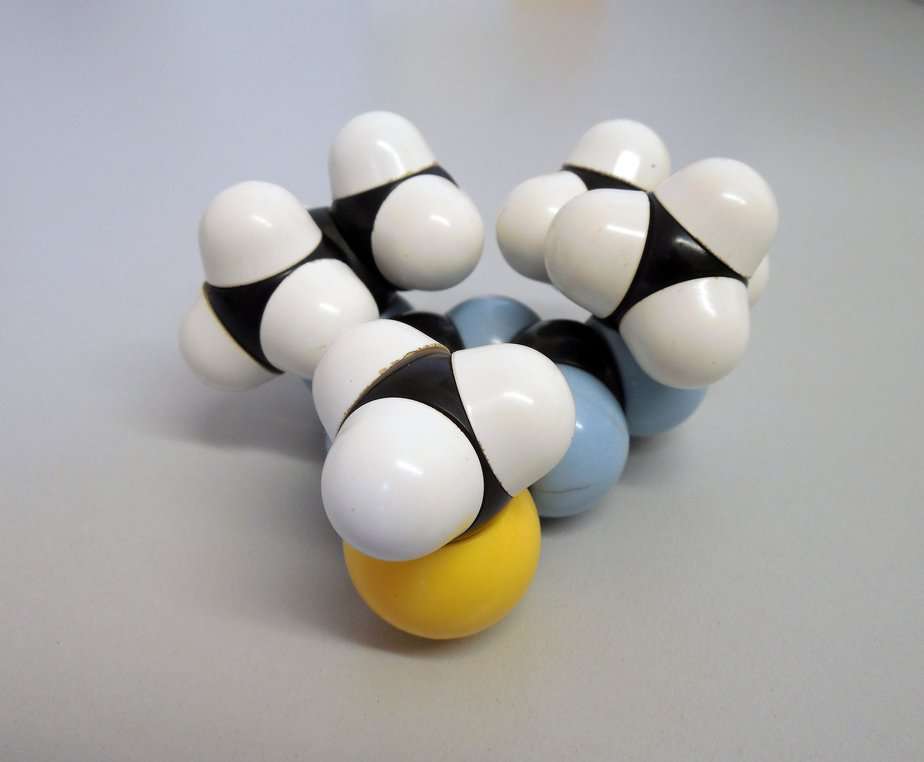

What Are Superabsorbent Polymers (SAPs)?

Superabsorbent polymers, commonly referred to as SAPs, are a class of synthetic polymers with a unique ability to absorb and hold onto large volumes of water or aqueous solutions. They were originally developed for various applications, including hygiene products like diapers, as well as in agriculture to improve water retention in soil. SAPs are renowned for their remarkable water-absorbing capacity, with some being able to absorb hundreds of times their weight in water.

How Do Superabsorbent Polymers Work?

The absorbent properties of SAPs stem from their molecular structure, which consists of a network of interconnected polymer chains with a high degree of cross-linking. This structure creates spaces or “pores” within the polymer matrix. When SAPs come into contact with water, the water molecules are drawn into these pores through a process called capillary action.

As the water is absorbed, the SAPs swell and expand, forming a gel-like substance. This gel retains the absorbed water, preventing it from escaping. This property makes SAPs useful in various applications where moisture control is critical.

Why SAPs Don’t Work for Dam Sealing

While superabsorbent polymers have proven invaluable in certain applications, they face significant challenges when used for dam sealing projects. Here are several reasons why SAPs are not the ideal solution for this purpose:

Limited Sealing Capability

The primary goal of dam sealing is to create a watertight barrier to prevent water from seeping through the dam structure. While SAPs are excellent at absorbing and retaining water, they do not inherently possess the ability to create a reliable, long-term seal. The gel-like substance formed by SAPs can be disrupted by external factors such as temperature fluctuations, pressure, and movement within the dam structure, compromising their sealing effectiveness.

Lack of Durability

Dams are subject to various environmental and structural stresses over their lifetimes. Superabsorbent polymers, once hydrated, can degrade over time. Exposure to UV radiation, extreme temperatures, and microbial activity can break down the polymer matrix, reducing its ability to maintain its water-absorbing capacity and integrity. This lack of resilience is a serious disadvantage for dam sealing applications where long-term performance is essential.

Limited Coverage

Achieving a comprehensive seal in dam structures often requires materials that can be evenly distributed across the sealing area, reaching all potential water pathways. SAPs are typically supplied as granules or powder, which makes it challenging to achieve uniform coverage in large and irregularly shaped dam surfaces. In contrast, traditional sealing methods like clay or geomembranes offer greater versatility in covering expansive areas effectively.

Incompatibility with Dam Materials

Dams are constructed using various materials, such as concrete, earth, rock, or a combination of these. SAPs may not be compatible with all dam materials, potentially leading to adverse interactions that compromise the structural integrity of the dam. In some cases, the expansion of SAPs could exert additional pressure on the dam, exacerbating existing issues.

Uncertain Environmental Impact

The environmental impact of SAPs used in dam sealing is a subject of concern. When SAPs degrade or release water, they may alter the surrounding ecosystem and groundwater quality. Ensuring the environmental safety of SAPs in dam sealing applications requires extensive research and monitoring, which can be challenging to implement effectively.

Conclusion

Superabsorbent polymers (SAPs) are undoubtedly impressive materials with their extraordinary water-absorbing capabilities. However, their suitability for dam sealing remains limited.

In the quest for effective dam sealing solutions, it is essential to consider established methods and materials that have a proven track record in providing the necessary structural integrity and water-tightness. While SAPs may find applications in other domains, the world of dam construction requires solutions that prioritize long-term durability and reliability above all else.

More reading

A comprehensive guide to dam sealing

Pingback: Let's Talk Dirty | Big Ditch Dam Building Company

Pingback: Why Trees Are Bad For Dams | Big Ditch Dam Building Company

Pingback: Why Watersave Won't Stop Your Dam From Leaking | Big Ditch Dam Building Company

Pingback: Beginner's Guide To Building A Farm Dam On Your Property | Big Ditch Dam Building Company

Pingback: Farm Dam Construction On Sloping Terrain: Design And Stability | Big Ditch Dam Building Company

Pingback: How To Prevent Dam Siltation: Strategies And Solutions | Big Ditch Dam Building Company

Pingback: Overflow Strategies For Earth Dams | Big Ditch Dam Building Company

Pingback: How To Use Bentonite To Seal A Dam | Big Ditch Dam Building Company

Pingback: Understanding The Water Requirements For Farm Dam Construction | Big Ditch Dam Building Company

Pingback: 10 Strategies For Adapting Dam Design For Climate Change | Big Ditch Dam Building Company

Pingback: Earth Dams On Farms: Balancing Agricultural Needs With Sustainable Water Management | Big Ditch Dam Building Company

Pingback: Super Absorbent Polymers: Production, Chemicals, And Environmental Consequences | Big Ditch Dam Building Company

Pingback: Earth Dam Geology: Site Selection And Assessment | Big Ditch Dam Building Company

Pingback: Does Polymer Innovations Dam Sealing Product 'Watersave' Work? | Big Ditch Dam Building Company