Alternative names:

Smectitic clay, Fullers Earth

Bentonite clay consist mainly of smectite minerals, of which the most common mineral species is montmorillonite.

A general formula for montmorillonite is (1/2Ca, Na)0.7(Al,Mg,Fe)4[(Si,Al)8O20](OH)4.nH2O

The montmorillonite minerals are products of volcanism and hydrothermal activity and are composed of hydrous aluminum silicates in the form of extremely small particles – and they take up water, causing swelling, and change the interlayer spacing according to the mineral variety.

Montmorillonites are the principal constituents of bentonite and fuller’s earth.

Bentonite occurs in rocks that were deposited in the Ordovician to Neogene periods (about 488.3 to 2.6 million years ago) and is formed by decomposition of volcanic ash or tuff, or sometimes from other igneous or sedimentary rocks. Andesitic to rhyolitic volcanic rocks are the most common primary source.

The final chemical character of the bentonite is dependent on the combined influences of the chemistry of the primary rock, the environment in which it was deposited and its post-formation history.

Bentonite is a very plastic clay that swells markedly in response to the addition of water.

This swelling property makes Bentonite useful as a sealant, since it provides a self-sealing, low permeability barrier. We call it bentonite for dam sealing.

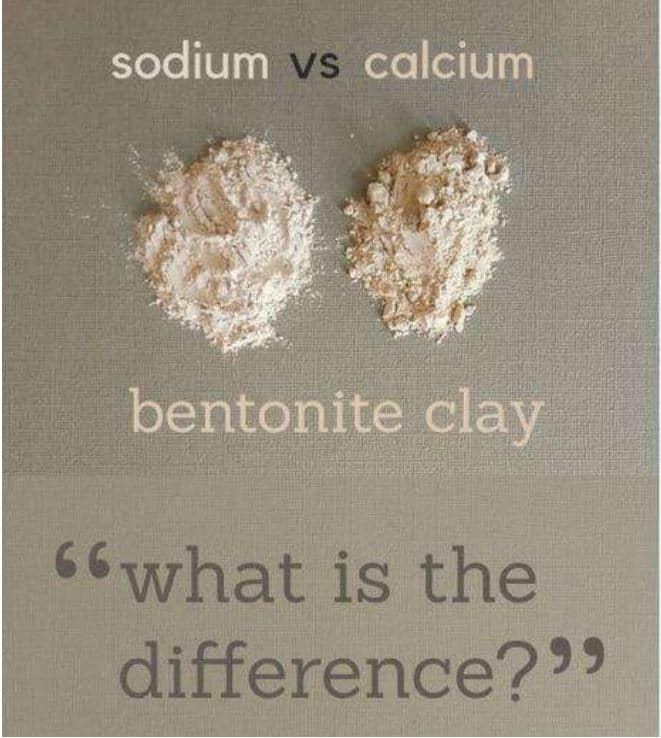

There are three main types of bentonite:

- high swelling (sodium)

- low swelling (calcium)

- moderate swelling (intermediate sodium-calcium) bentonite.